- An ISO Certified Company 2009:2015

- Mobile: +91 9725558549

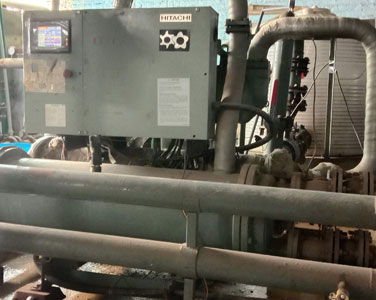

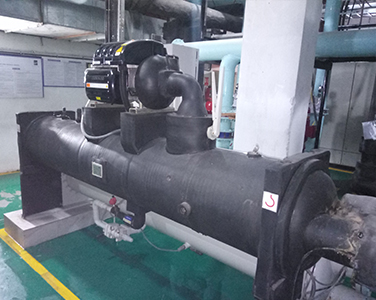

Water Chiller Service in Silvassa

The term is typically used to refer to a device that chills fluids, such as water, while there are a variety of chillers, including air-cooled chillers. That type of device is constructed with a compressor, condenser, an evaporator and a thermal expansion valve. For many jobs, including cooling a building along with numerous industrial applications, chillers are a valuable tool. So, you need to have it maintained on a regular basis through Water Chiller Service in Silvassa

How it works

To cool a liquid begins with the device's compressor is how the process a chiller executes. Starting the cooling cycle as a hot compressed gas the chiller's compressor pumps refrigerant inside,. This refrigerant is pumped to the condenser, which begins to condense the gas into liquid as it becomes cooled by a fan.

During this step in the process, much of the heat is blown out of the chiller. Once the gas has gone through the condenser and has become a cooled liquid, it moves on to the thermal expansion valve. From here the amount of refrigerant that enters the evaporator can be controlled. When refrigerant makes its way into the evaporator, it absorbs heat and then boils off, which causes it to turn into a vapor. Then water is sent through the evaporator that is heated by the refrigerant. From here, the refrigerant enters the compressor again, is turned into that initial hot compressed gas mentioned earlier and is sucked into the condenser. This leads back to the beginning of the cycle. For any assistance you can get in touch with the Water Chiller Manufacturer in Silvassa.

Role played by chillers

Chillers are present in air conditioning systems. Their role is that of a chilled water system during the process of cooling the air. This process is cyclical. A chiller used for an air conditioning system can be anywhere from 15 to 1,500 tons and cools water to a temperature of 35 to 45 degrees Fahrenheit. If you face any issues contact chiller maintenance service in Silvassa.